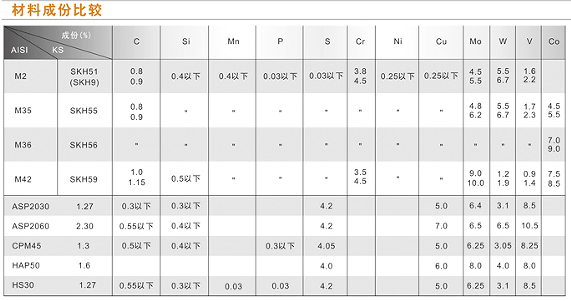

Comparing composition of raw material for hobs

Comparing composition of raw material for hobs

High speed steels may be divided into normal high speed steels, also referred to as HSS and into high speed steels that are made of powder which are generally known as PM (Powder Metals).

M2 - This is the traditional type of steel which has been used for decades in the manufacture of hobs. Nowadays it is not used very often and only on tools that do not endure much strain, that are used on old machinery or on standard tools where manufacturing speeds are not particularly important. This is the most economic steel.

M35 - This steel is used a lot since it has a high percentage of cobalt and therefore good wear resistance properties. It is a very tenacious steel and it is therefore suitable for hobs that endure a lot of strain. Modern coating technology with TiN or TiAlN help reduce crater-type and abrasive-type wear and therefore this steel makes hobs of excellent quality.

- Complete Gear Data for Ordering Gear Hobbing Tools

- PA20° Profile DIN3972 Standard Gear Hob Cutter with Module m4.5

- PA30° PCD 100mm Bowl Type Gear Shaper Cutter with Module m5~m10

- PA20° Module m1 Standard Involute Gear Hob

- PA20° Pre-shaving Gear Cutting Hob with Module m3.75

- PA20° DIN3972 Standard Gear Hob with Module m18

- Technical Information for Hobs