Hob Resharpening

Hob Resharpening

Resharpening time shoud be decided not to be late for better efficiency, the guidelines for determining the time to resharpen are follows:

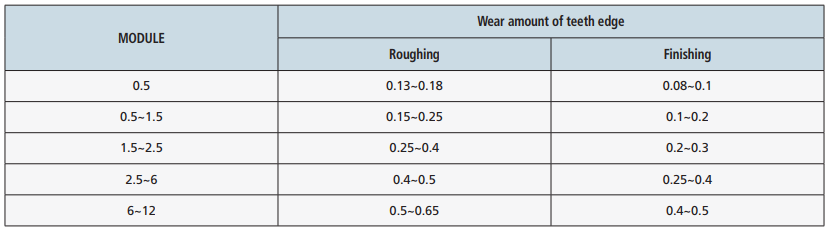

1,wear amount, when the gear is cut by roughing or finishing process, the hob wear amount can be different. Generally, it is recommended to regrind per chart below.

2,tool life, to preserve an optimum cutting condition and get long tool life, a tool should be resharpened after checking the wear amount. If you use a worn tool, the tools' cutting ability is reduced.

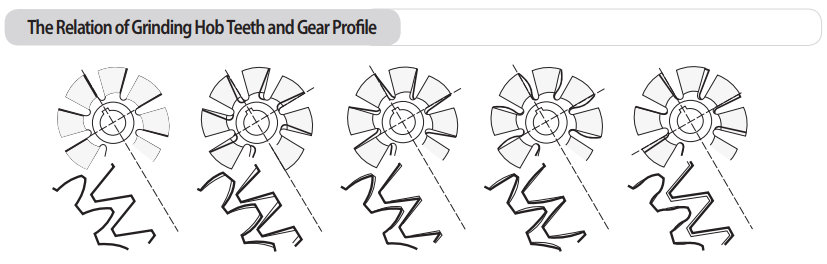

during grinding,if you exceed the proper grinding amount an invisible grinding crack may occur so it makes the tooth separate and causes the hob to break. If you suspect that a grinding error has occurred, continue to inspect the teeth and if you notice any color variation, this could be an indication that a crack has formed and you stop using the hob.

please visit our new website and contact us for more details precision gear hobs.

- Parallel Side Spline Broach

- PA20° DP4.5 Standard Gear Cutting Hob with BPⅡ

- PA30° DIN5480 Involute Spline Hob Cutter with Module m3

- PA20° DIN3972 Standard Gear Hob with Module m16

- PA20° Pre-shave Gear Hobbing with Module m2.25

- PA20° Standard Gear Milling Cutter with Module m5

- Timing Pulley Hob for (AT.)D.T (D)T5