Effect of Hob Sharpening Errors

Effect of Hob Sharpening Errors

Hobs resharpened on an arbor in resharpening machine that runs eccentrically will result in sharpening errors that give the same 11wandering 11profile characteristic to an involute profile as an eccentrically mounted properly sharpened hob in a hobbing machine. Other sharpening errors to the base rack that effect hob profile are

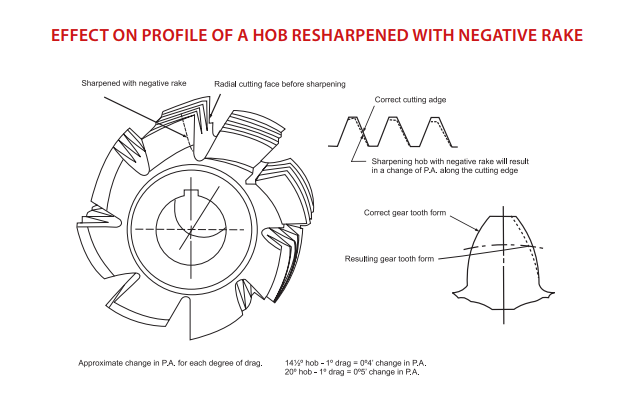

Hob cutting faces are sharpened with negative rake.

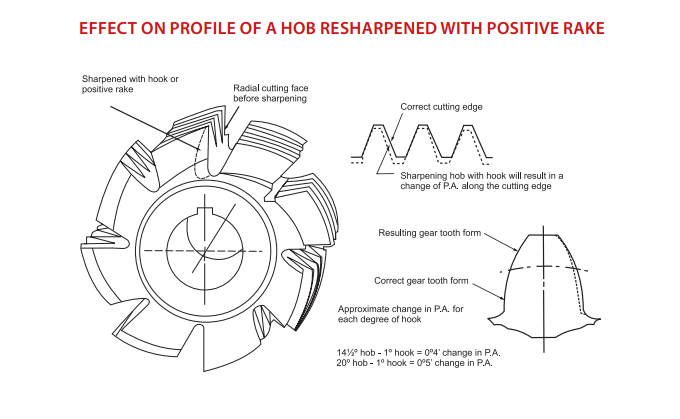

Hob cutting faces are sharpened with positive rake.

Hob cutting faces are sharpened by unequal amounts resulting in uneven flute spacing.

A hob sharpened with incorrect lead will result in one end of the hob being larger in diameter than the other. As the hob is shifted across its usable life in the hobbing machine, a change in the size of the work piece will be evident.

- K40/K42 Solid Carbide Gear Hob Cutter for Oil-Cooling Cutting

- PA30° PCD 100mm Bowl Type Gear Shaper Cutter with Module m5~m10

- HSS M35 Material Gear Hobbing Tools and Involute Gear Hobs with AP Coating

- Disk Type Shaper Cutters with JIS B 4356

- Keyway Broach

- PA20° Standard Gear Milling Cutter with Module m1.5

- Shank Type Worm Gear Hob with Module m7